説明

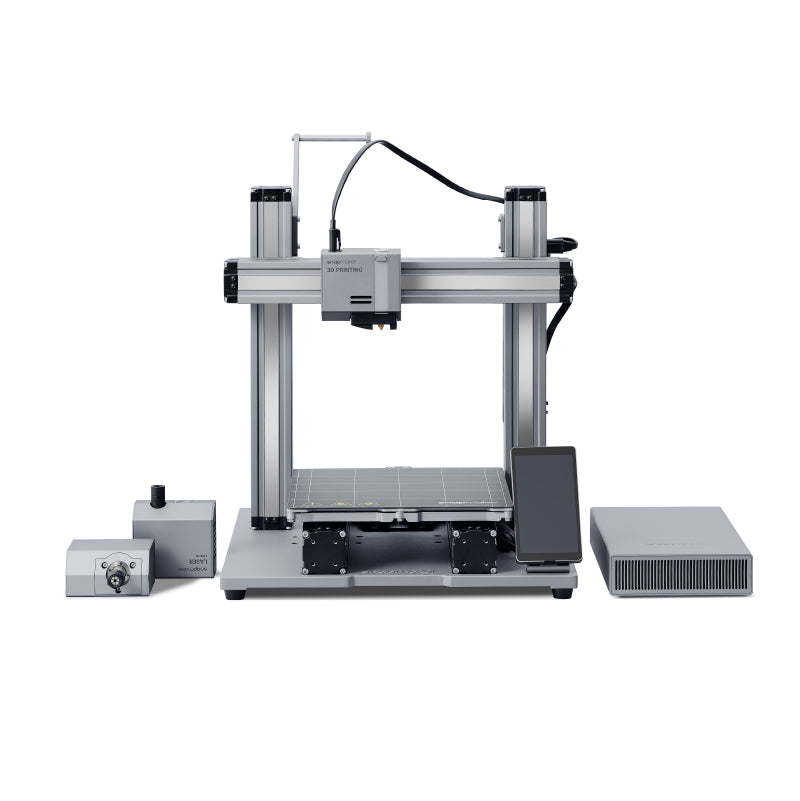

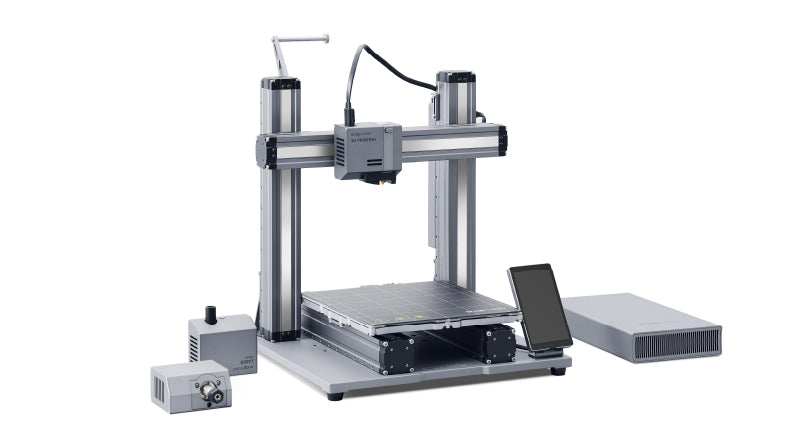

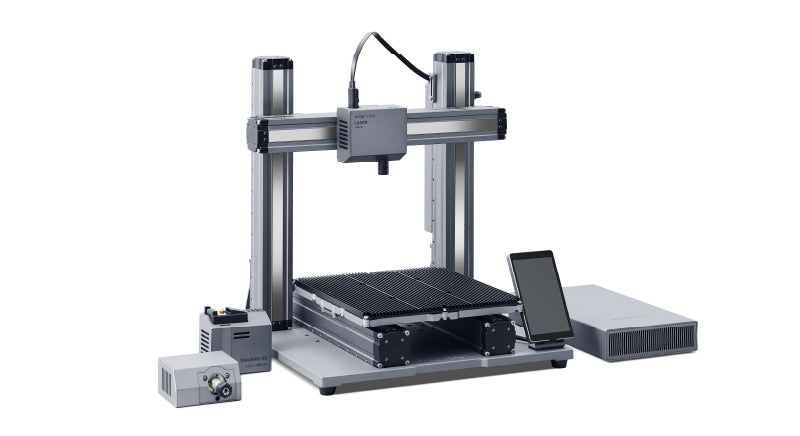

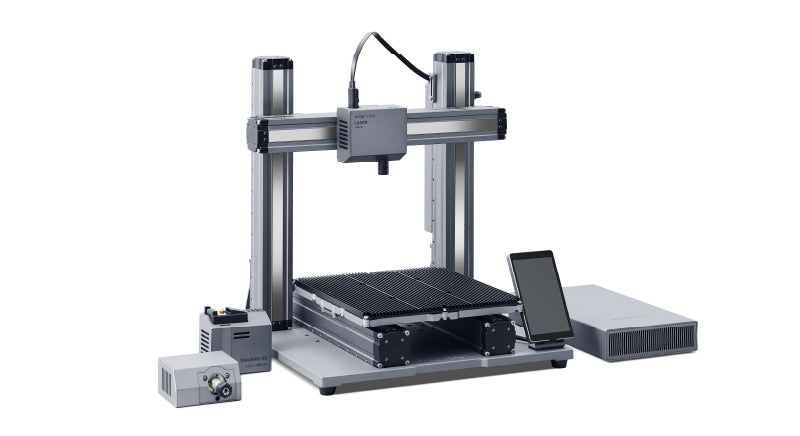

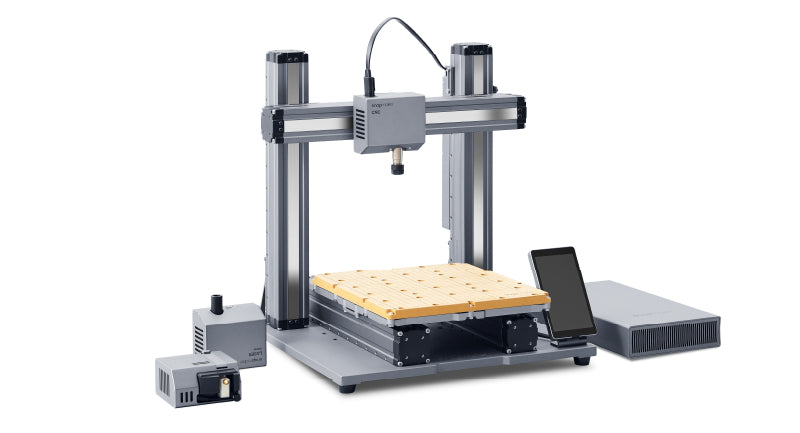

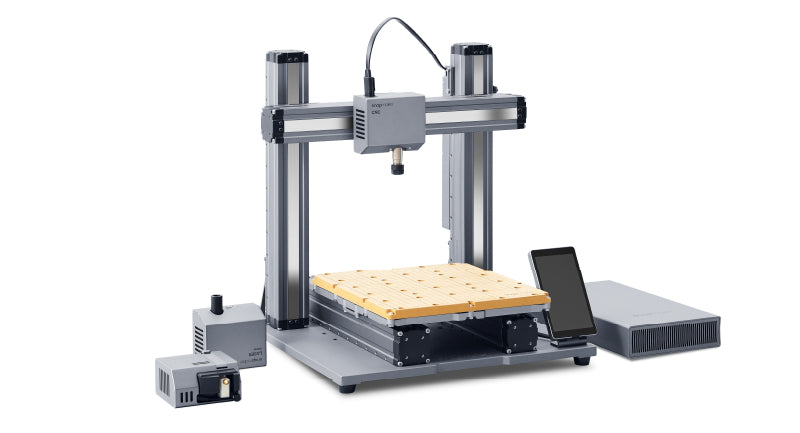

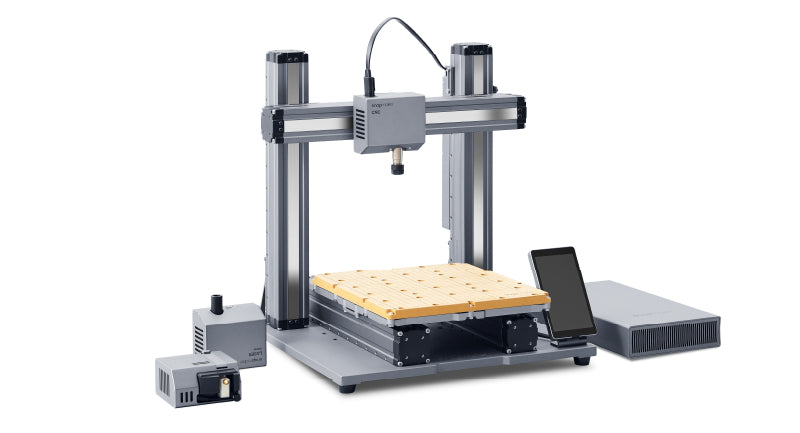

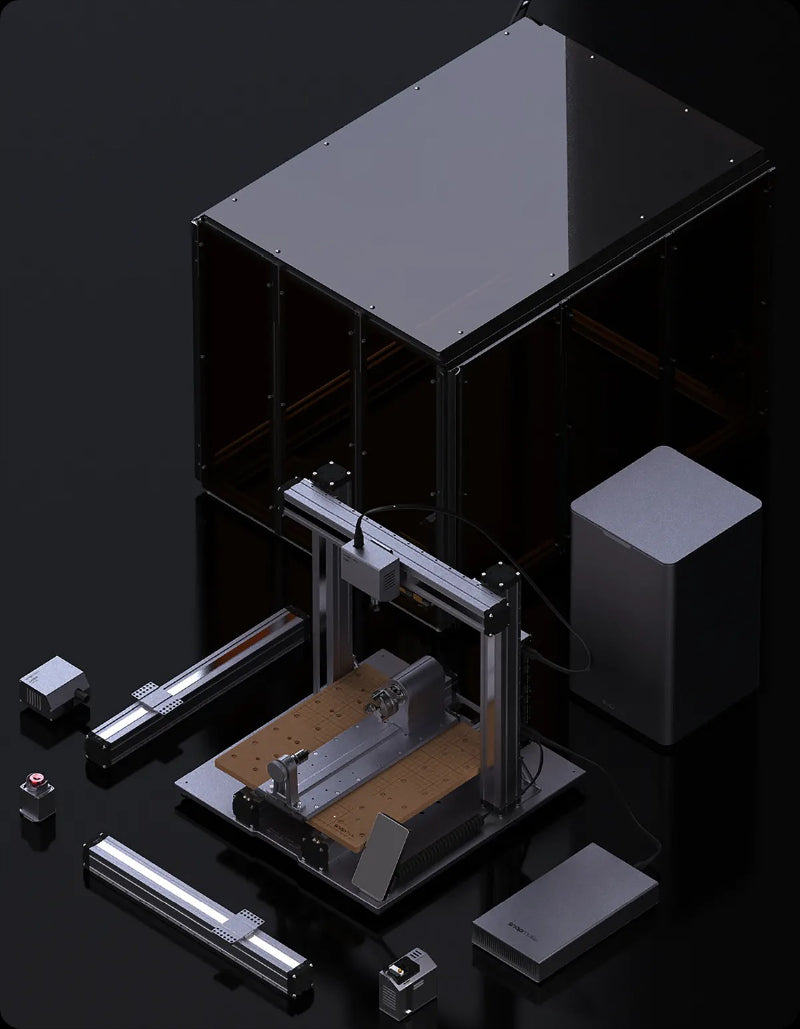

3つの機能がコンパクトにまとまったスマートなモジュール式

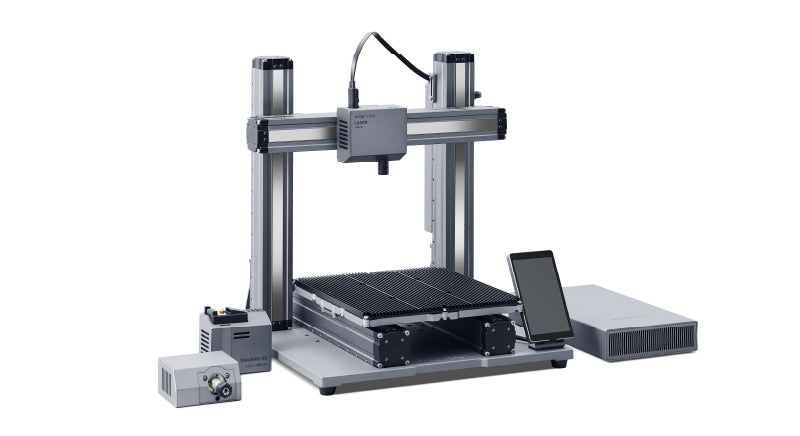

Snapmaker(スナップメーカー)2.0 多機能3Dプリンターは、3-in-1(スリーインワン)大きく3つの機能が特徴の3Dプリンターです。

この1台で3Dプリント、レーザー彫刻、CNC彫刻ができ、あなたの3D表現の可能性を広げるマシンです。

コンパクトなサイズに必要な物が全て備わっています。

自由な発想で、3Dプリントや彫刻を楽しんでみてはいかがでしょうか。

A250Tには、Snapmaker A350およびA250に基づいた今までの経験とアップグレードがあり、より高速で静かな印刷技術を提供します。

1台で3Dプリンター、レーザーカッター、CNC(機械加工)を実現!

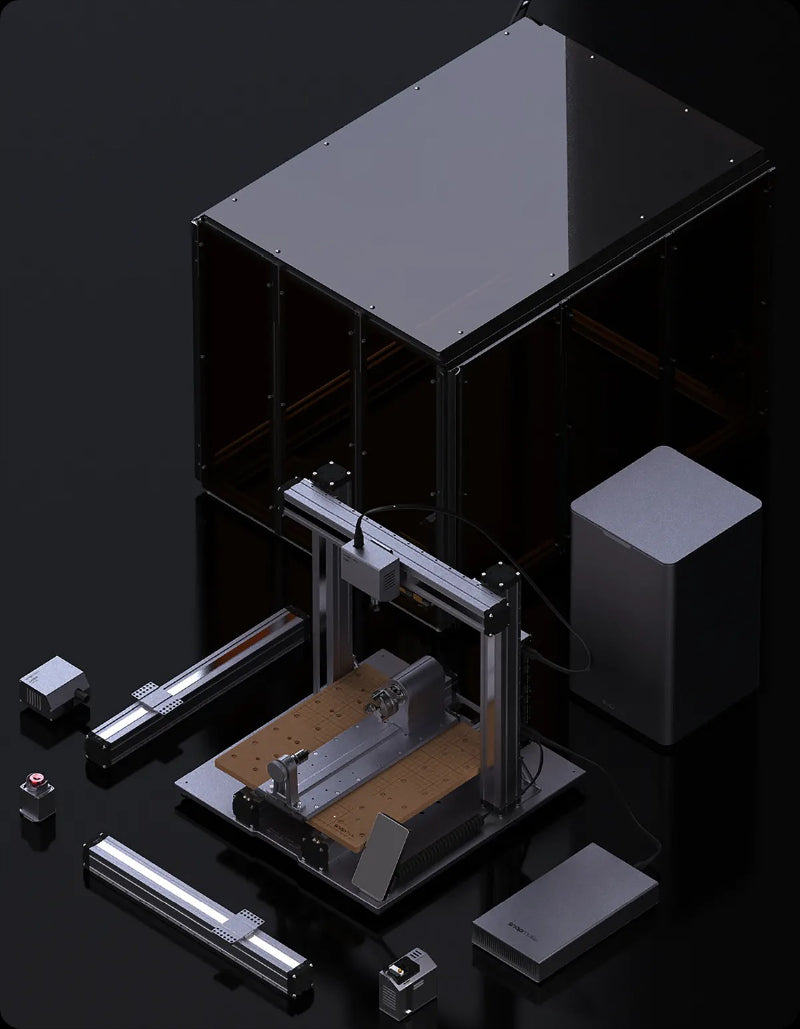

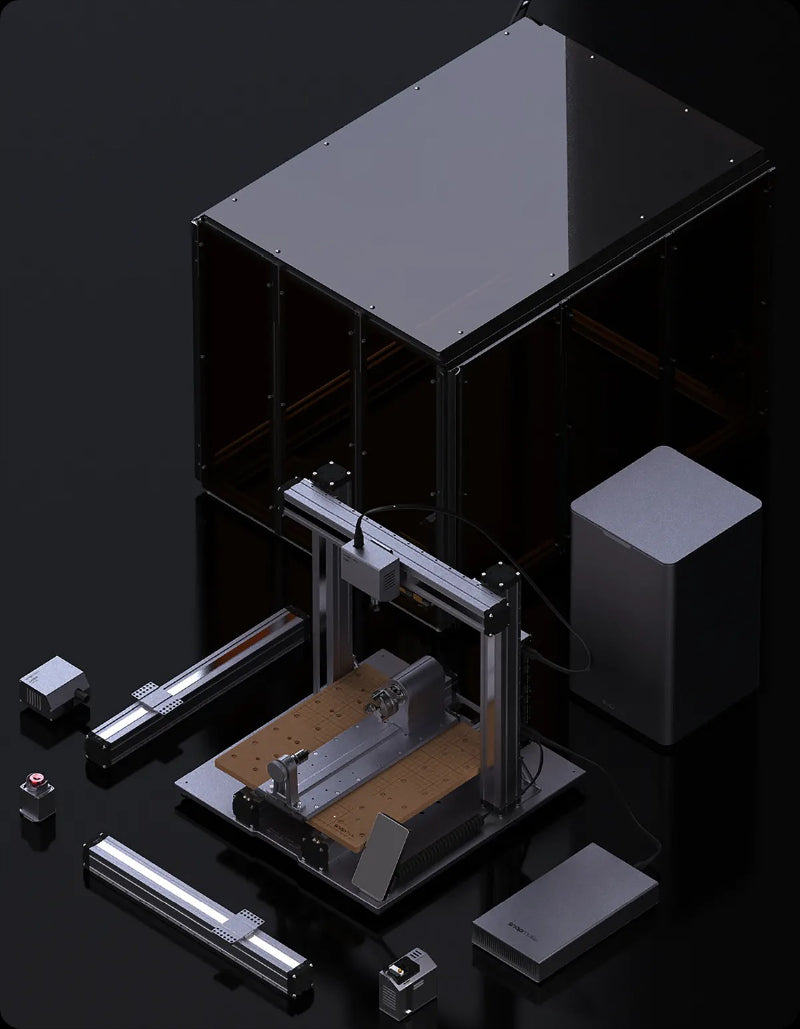

3Dプリント、レーザー彫刻、CNC彫刻の3つの機能を備えながらも、専用エンクロージャーによって、安全に加工作業を行うことができます。

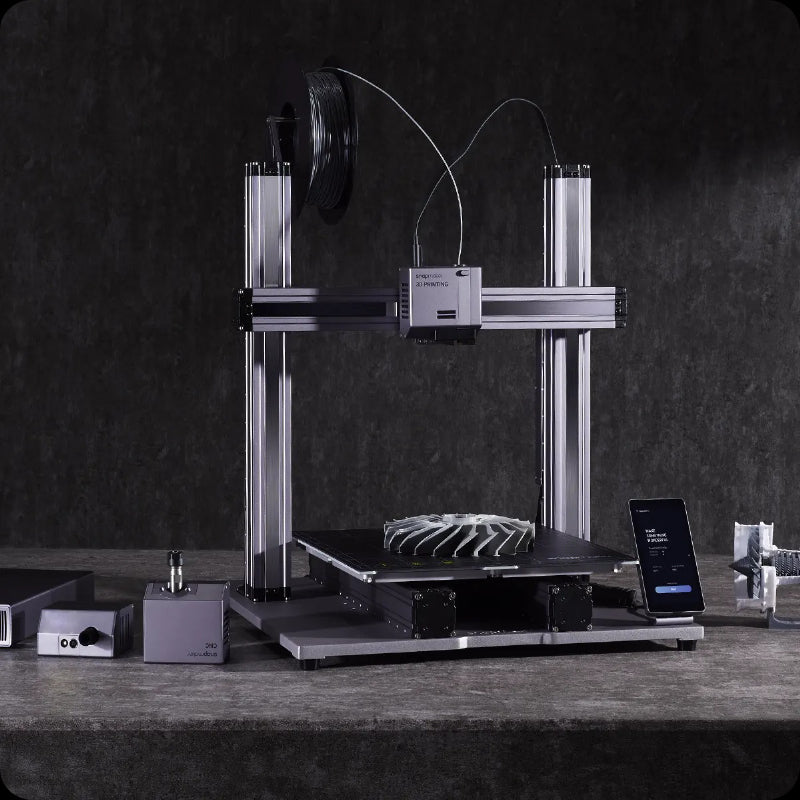

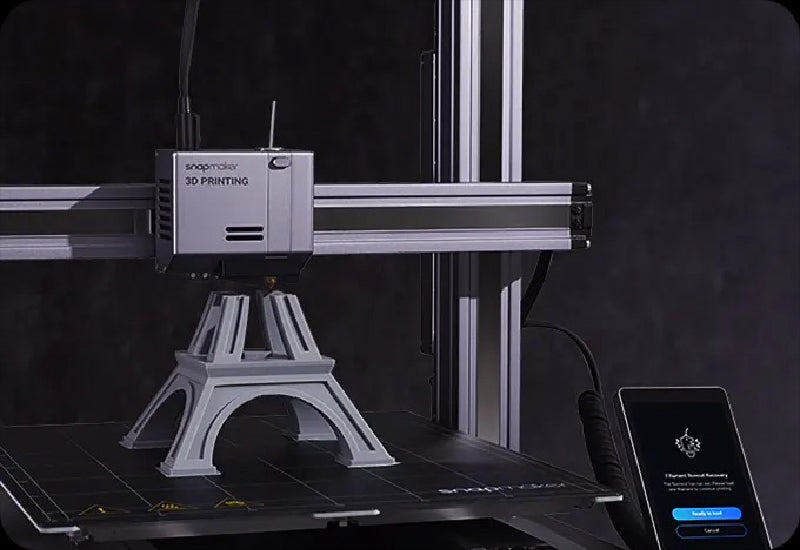

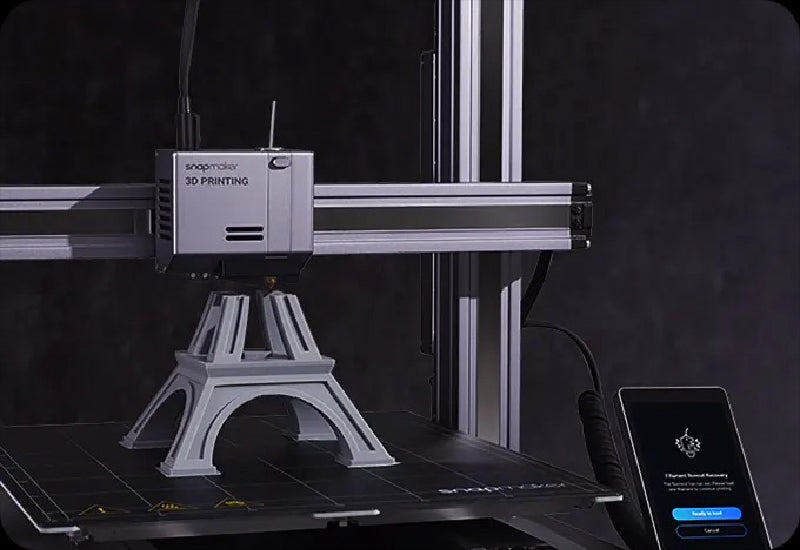

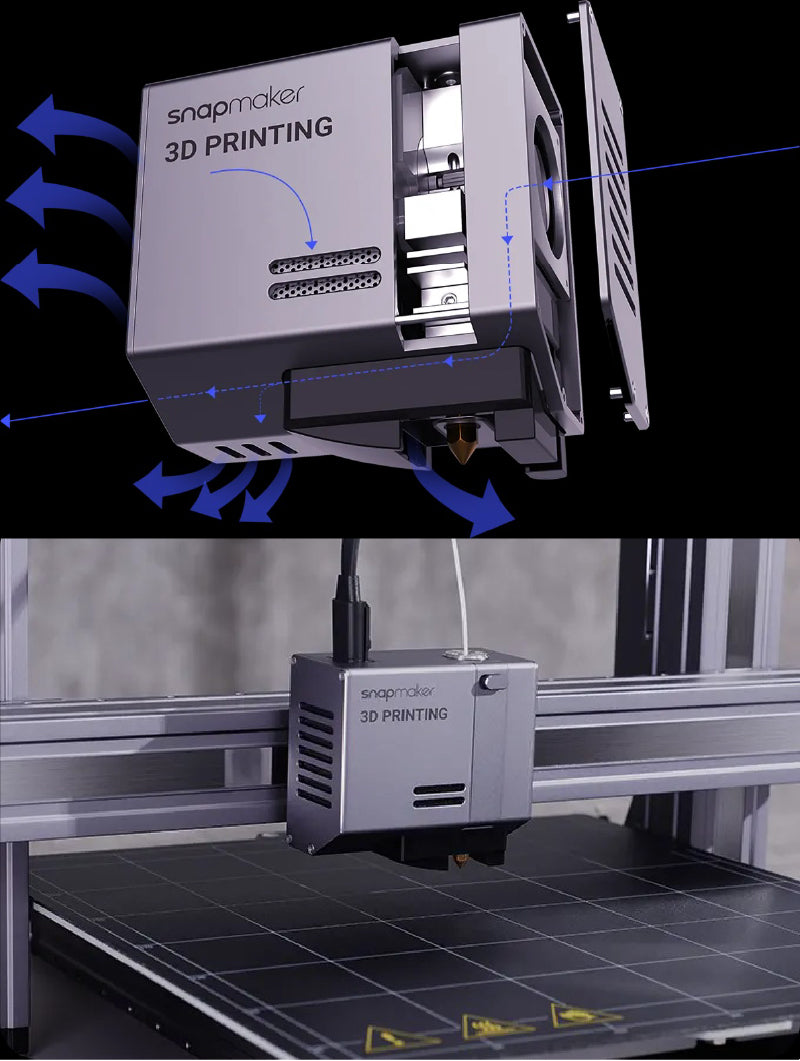

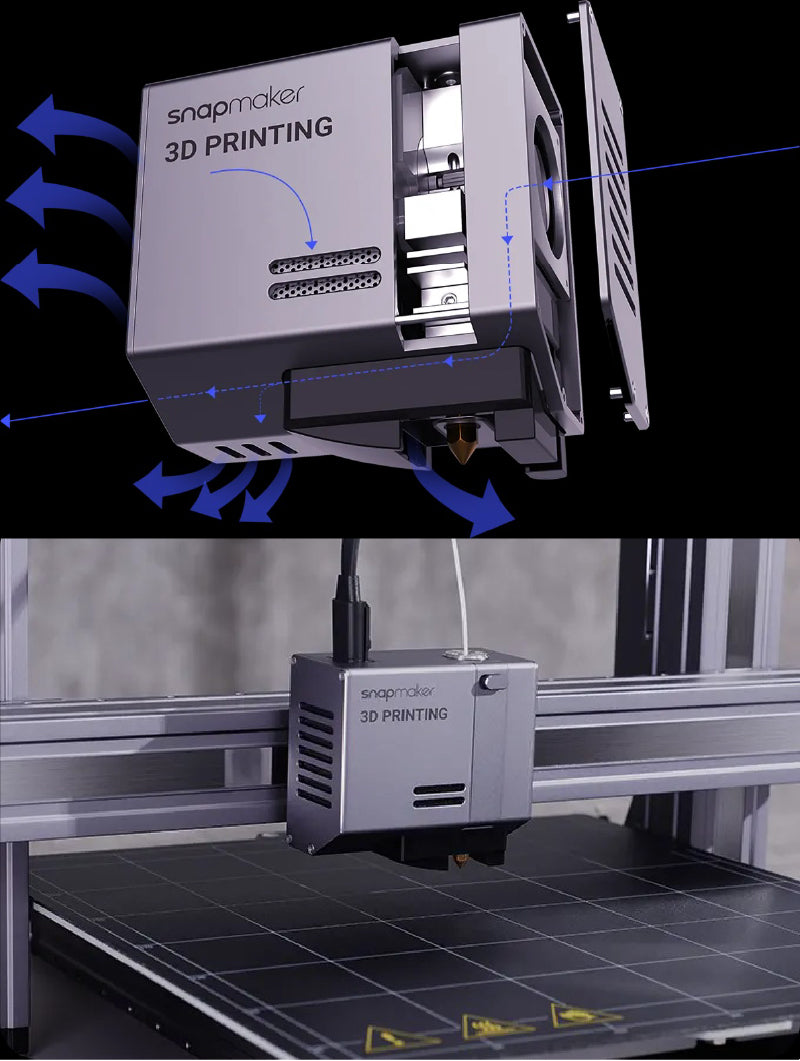

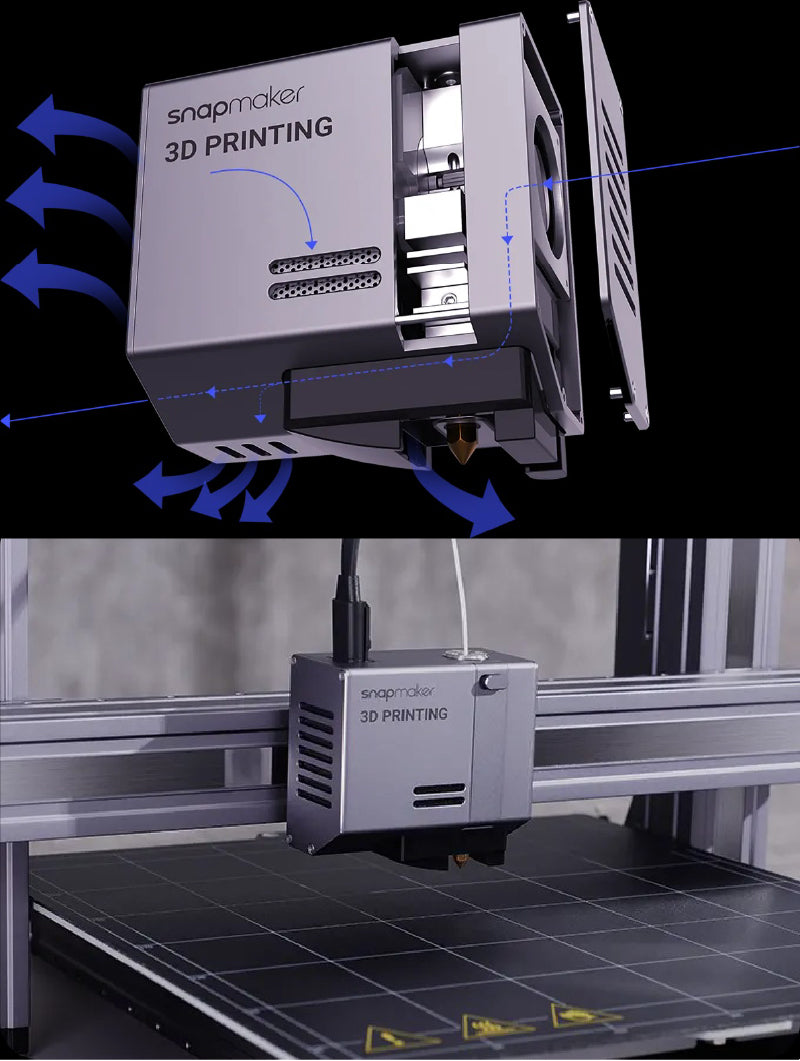

3Dプリント機能

Snapmaker 2.0シリーズの3D印刷モジュールは、数十の材料をサポートします。積層ピッチは0.05〜0.3mmから選択できるため、非常にきめ細かな細工が可能。

また、オートキャリブレーションに対応しているため、面倒な事前準備が不要です。

内蔵された近接センサーによって、加工位置を自動的に校正できます。

手動モードに切り替えて、きめ細かくキャリブレーションすることもできます。

Snapmaker 2.0 A250Tにはフィラメントの状態を検出するセンサーが内蔵されており、フィラメントが切れるとマシンを一時停止します。

新しいフィラメントを入れて、タッチスクリーンを操作するだけですぐに印刷を再開します。

停電後で印刷作業が中断されても大丈夫。

タッチスクリーンをタップするだけで、中断したところから再開できます。

※ ABS素材を使用すると、印刷がゆがむ可能性が低くなるため オススメです。

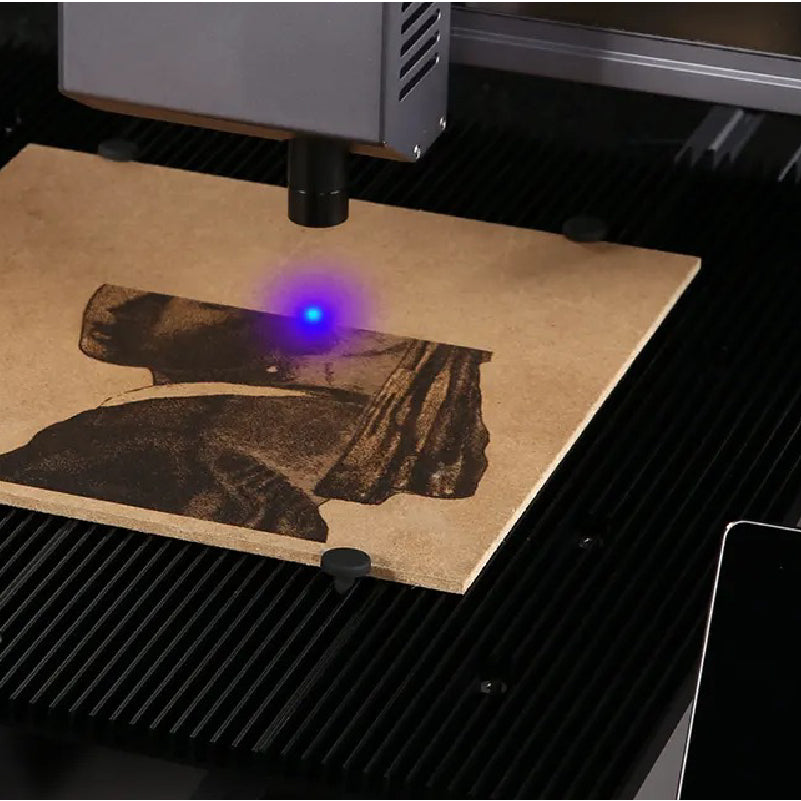

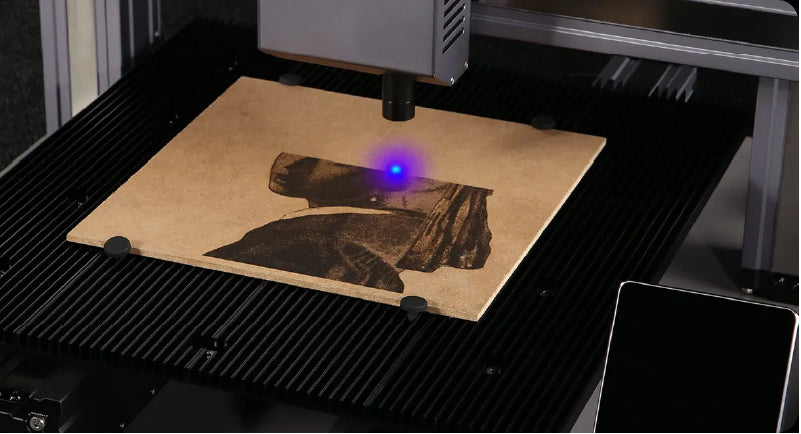

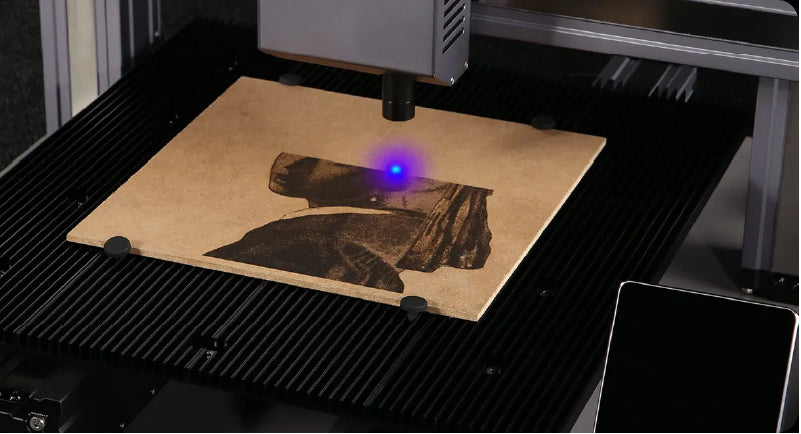

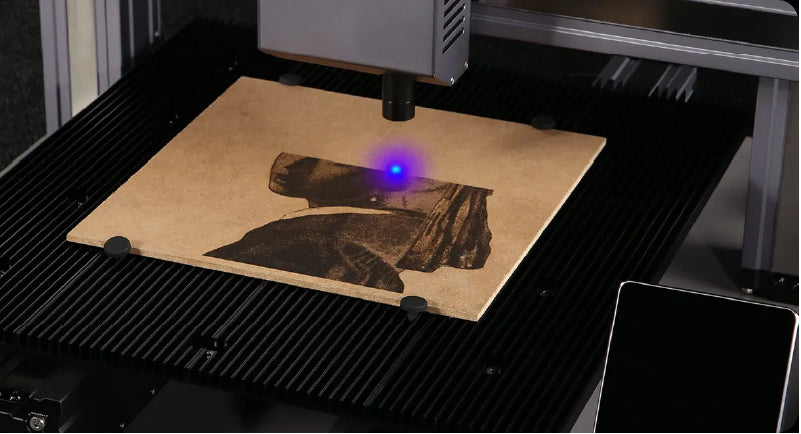

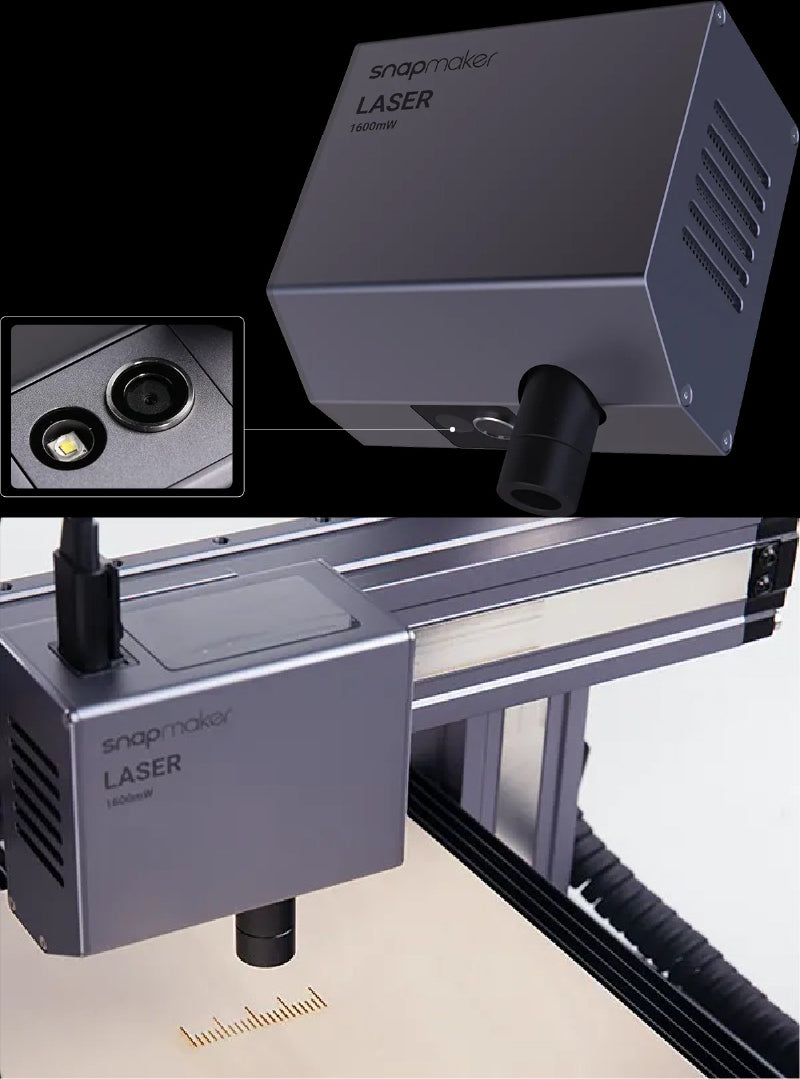

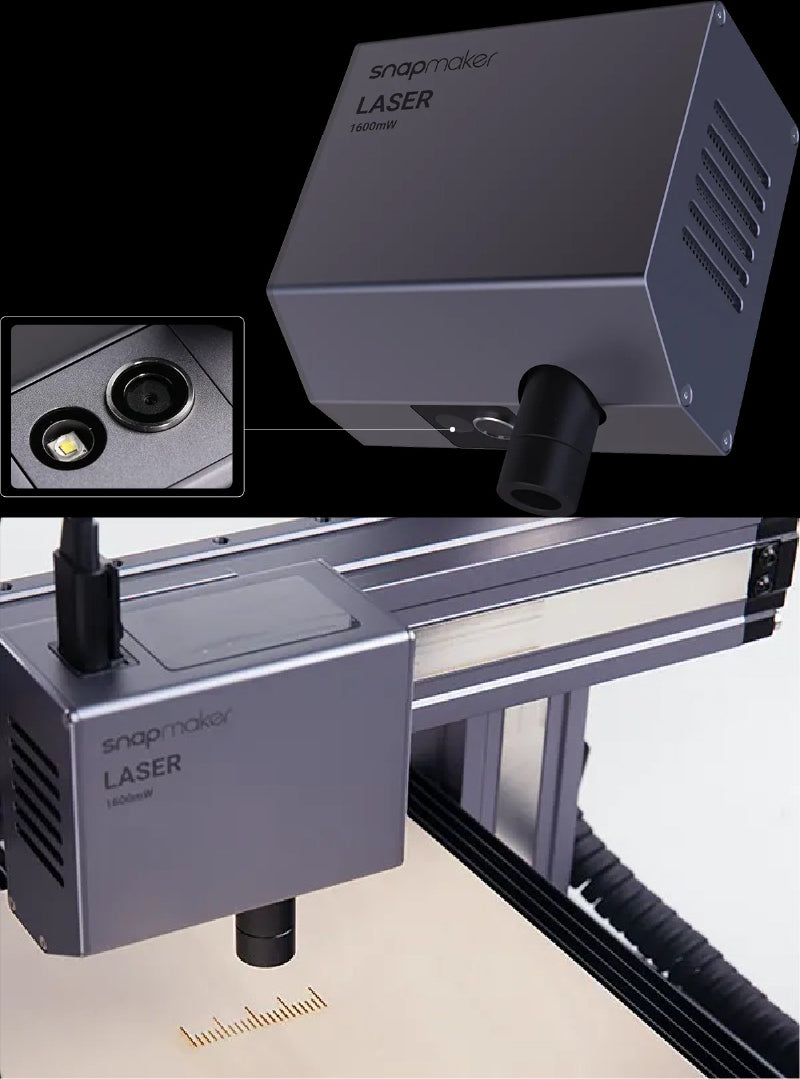

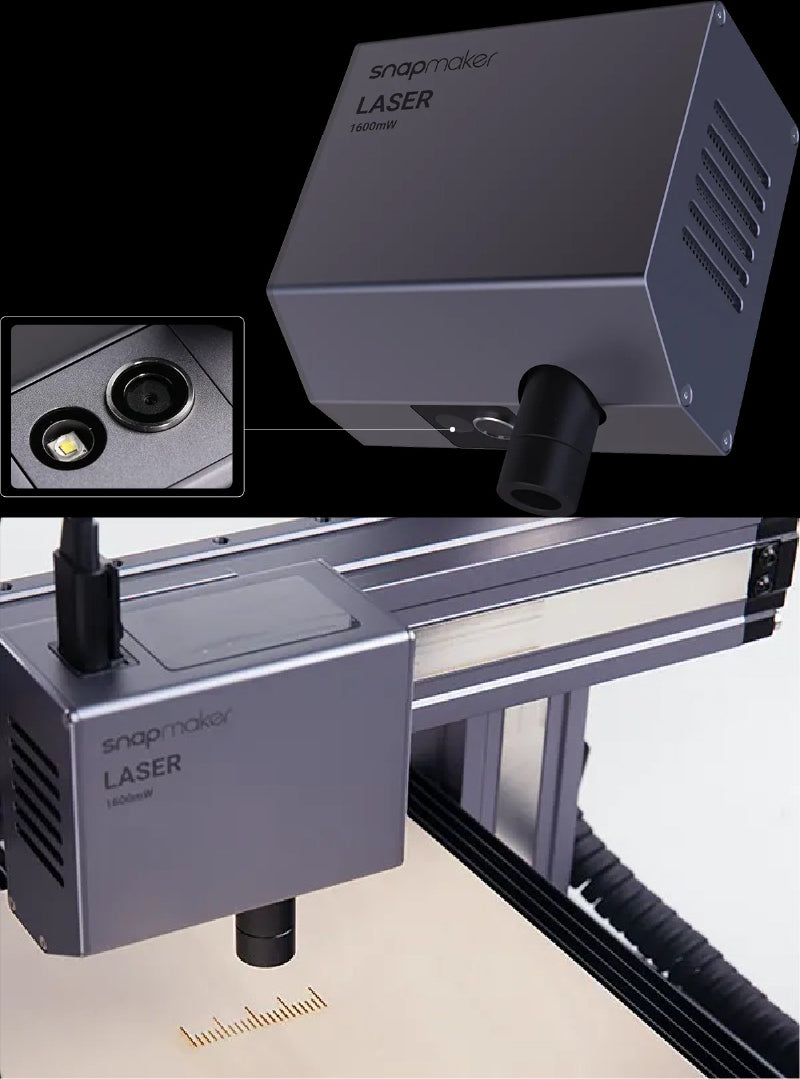

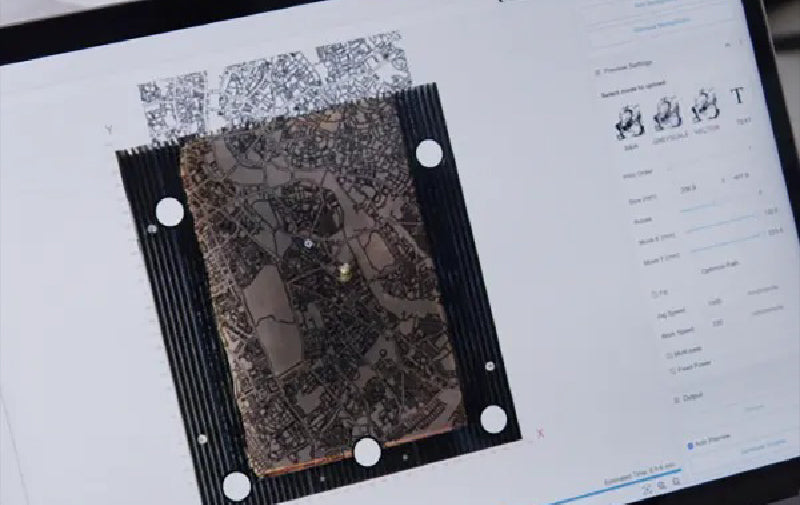

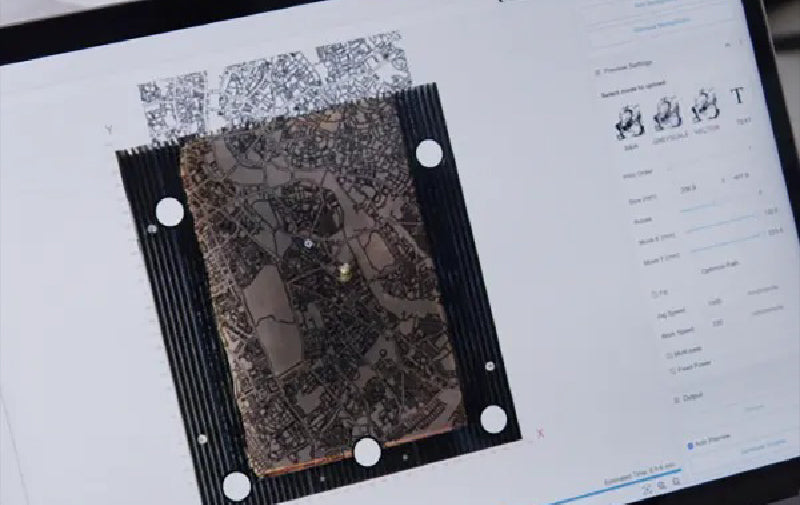

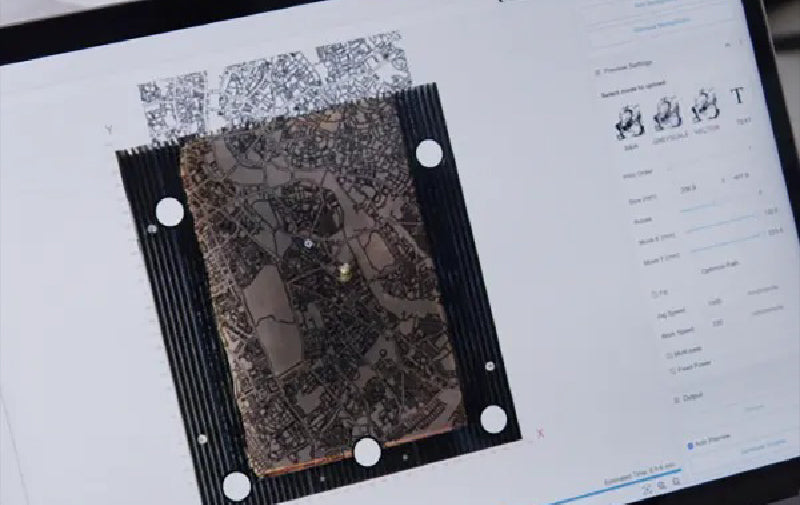

レーザーカッター機能

1600 mWのレーザーカッター用モジュールは、木材、皮革、プラスチックなどの素材を彫刻および切断できます。

内蔵カメラはオートフォーカスとカメラキャプチャ機能を有効にします。つまり、レーザーの焦点を合わせる時間を短縮し、最適な彫刻結果をより簡単に得ることができます。

オートフォーカスに対応しているため、面倒なレーザーの焦点の調整を繰り返す必要がありません。

内蔵カメラによって最適なレーザー高さが自動的に使用されます。

カメラは自動的に素材の状態を撮影し、専用ソフトのSnapmaker Lubanと連動します。

画像を直接インポートして編集し、クリックするだけでソフトウェアに表示されている通りの精密な彫刻が可能です。

CNC(機械加工)機能

CNCモジュールではER11コレットを使用することで、安定した加工が可能です。

ビットは直径0.5〜6.35 mmと互換性があるため、様々な材料を加工できます。

回転速度を6,000〜12,000 RPMで調整することで、素材に合わせた最適な加工が可能です。

エンクロージャーによってノイズレベルを最大10dBA低減できるので、CNC彫刻の音も従来より抑えられます。

フルメタル素材とモジュール設計で無制限カスタマイズ

マシンとエンクロージャーの両方が高性能アルミニウム合金を使用しており、モジュール式で組み立てができます。

自動車および産業用自動化で広く採用されているCAN(Controlled Area Network)バスシステムを使用しています。

Snapmaker 2.0シリーズはモジュールを組み合わせることで、多彩な加工に対応します。

すべてのポートが標準化されており、将来的にはさらに多くのアドオンがリリースされる予定です。

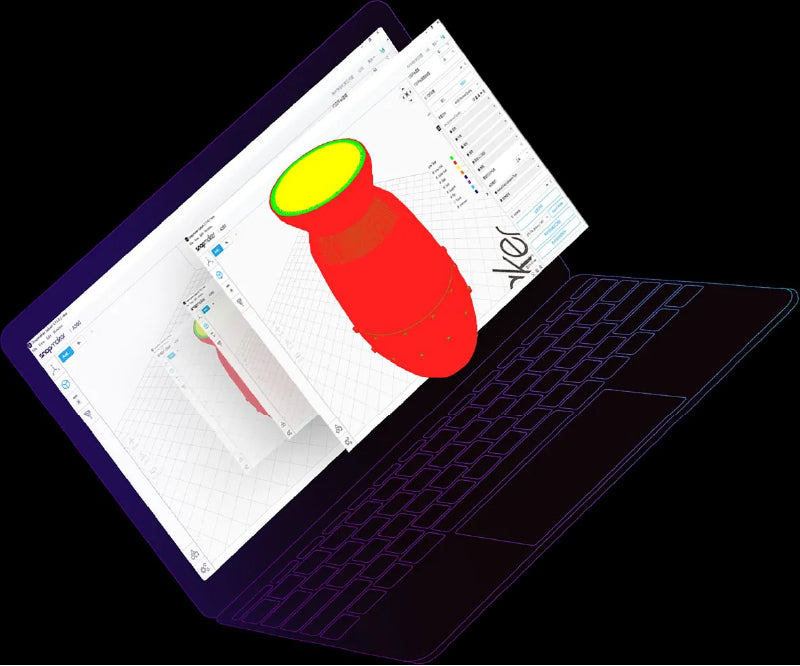

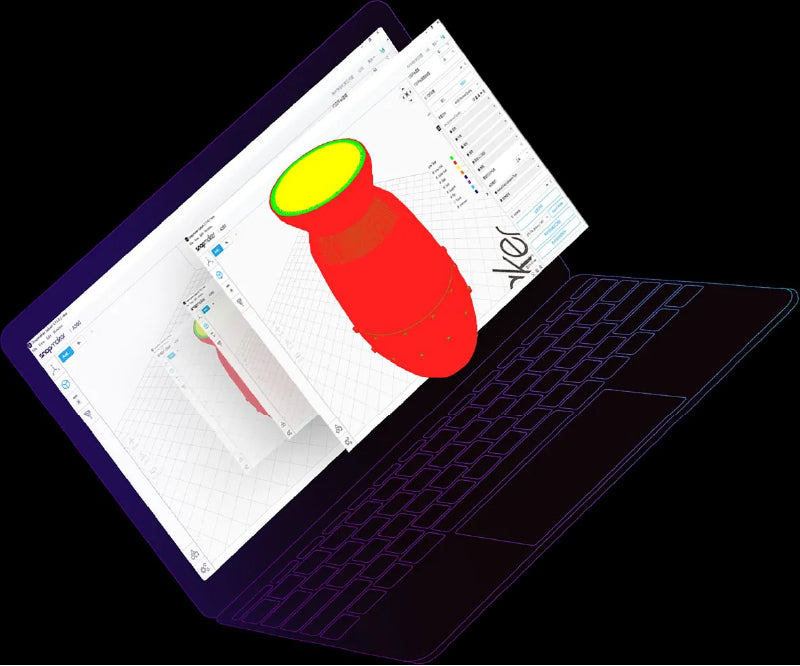

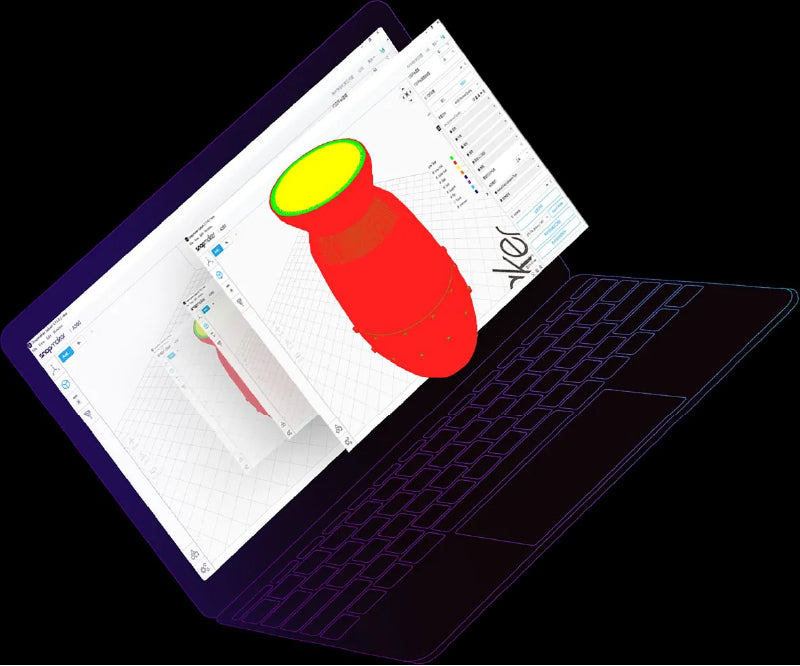

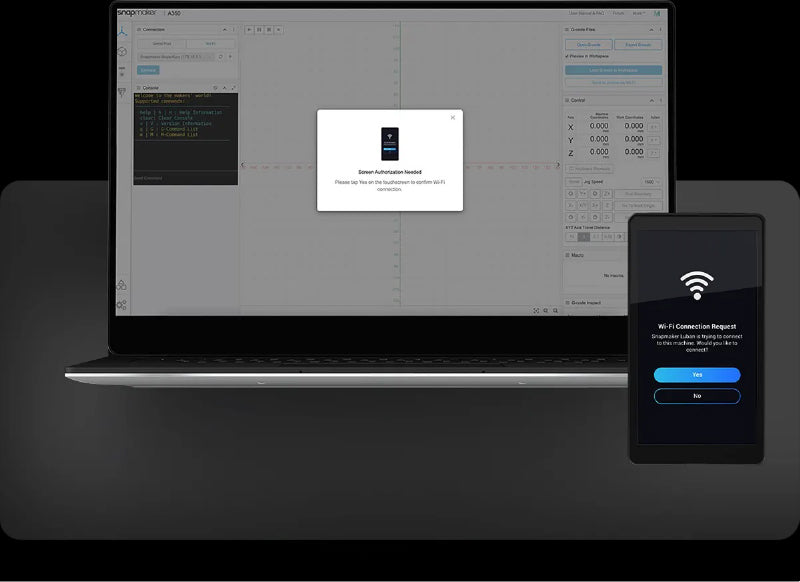

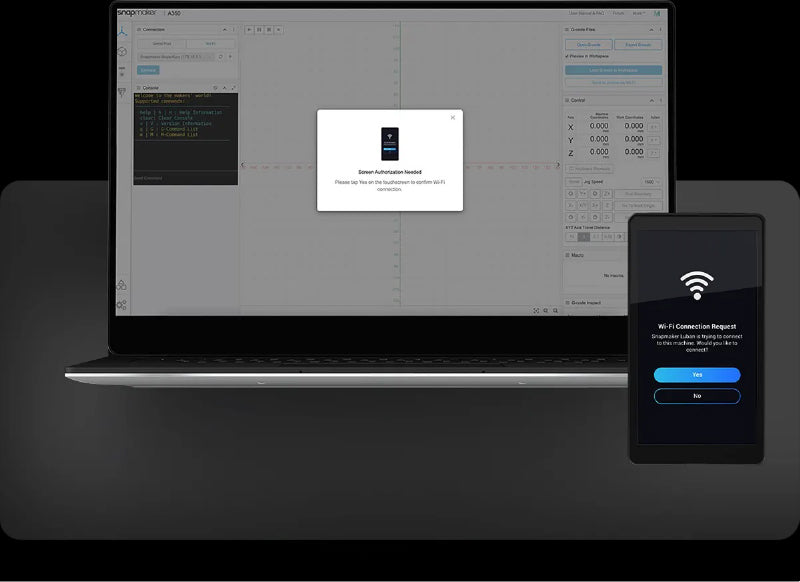

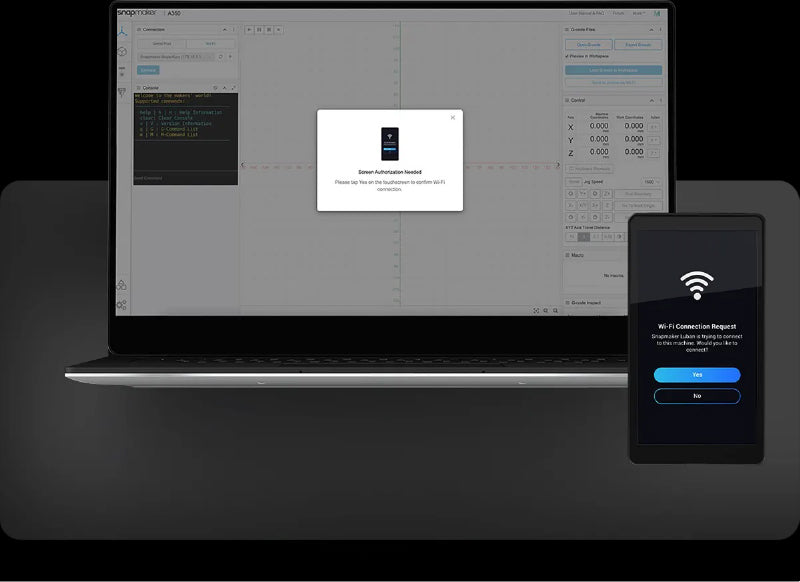

3-in-1ソフトウェア、Wi-Fiリモコン

専用ソフトウェアSnapmaker Lubanを使えば Snapmaker 2.0 A350の自動制御に必要なGコードファイルを素早く作成できます。

プリセットを選ぶことで、複雑な調整とテストをスキップし、すぐに作成を開始できます。

Snapmaker Lubanを使用してWi-Fi経由でA250Tを接続および制御し、ファイルをワイヤレスで送信します。

また、 4コアの高性能プロセッサを搭載したAndroidベースのタッチスクリーンを内蔵。

最新のスマートフォンのような滑らかな操作性です。さらに OTA(無線)アップグレードをサポートしているため、最新機能がリリースされたらすぐに楽しむことができます。

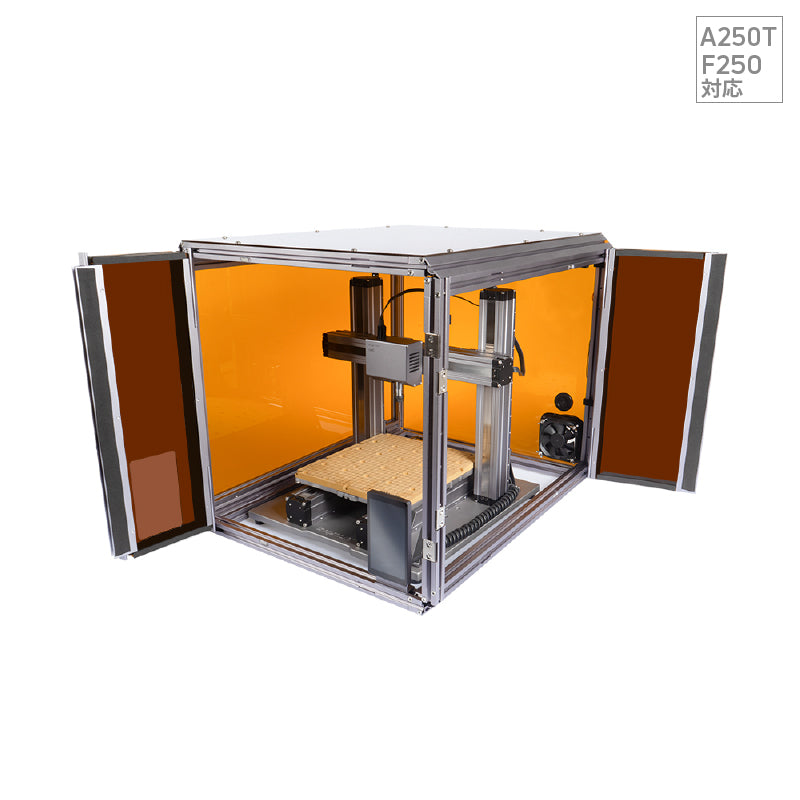

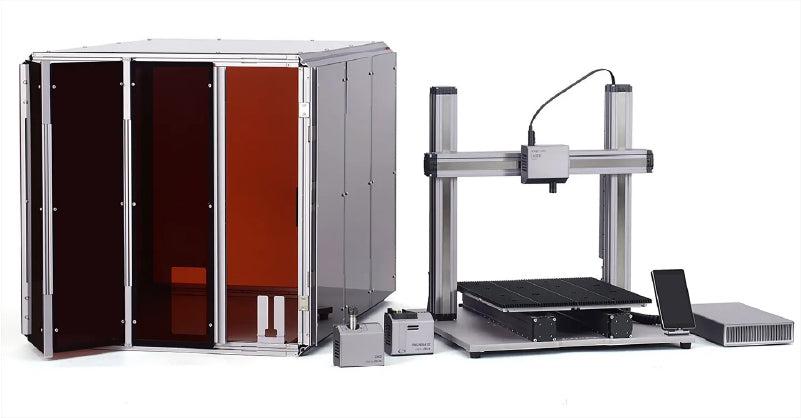

安全性とエコ環境を提供するエンクロージャー

Smapmaker2.0 A250Tは専用エンクロージャーとの組み合わせがオススメです。

エンクロージャーによって加工時も安全で、騒音も 最大10dBA低減できます。

もう、加工作業のために地下室やガレージは必要ありません。

パネルとドアは茶色のアクリルでできており、有害なレーザーから身を守ります。OD6レーザー安全ゴーグルのペアも付属しています。

内蔵ファンによってレーザー加工中の煙を排出します。

レーザー彫刻またはCNC彫刻中に一方または両方のドアが開かれると、マシンは自動的に一時停止します。

LEDライトで照らされるため、加工作業時の様子を確認できます。

フィードバッグに応えた嬉しい仕様

・ノイズリダクションチップ

レベルは異なる場合がありますが、機械の特定の部分で動作中にノイズが発生する可能性があります。新しいリニアモジュールでは、TMC 2209ステッピングモータードライバーチップが組み込まれているため、ノイズが大幅に低減されます。

・リニアモジュールのリード最適化

静かな印刷は必ずしも速度が遅いことを意味するわけではありません。 Snapmakerは、それに応じてX軸とY軸のスクリューロッドのリードを8mmから20mmに増やし、安定した高速の作業速度を保証します。

・パワーモジュールの改善

新しいパワーモジュールは、はるかに静かなファンを使用しており、その速度はリアルタイムの温度に合わせて自動調整し、約16dBA のノイズレベル低下を実現しました。

Snapmakerシリーズ

・3Dプリントの機能に特化→ Snapmaker 2.0 Fシリーズ

・より大型の3-in-1タイプ→ Snapmaker 2.0 A350

製品詳細

Snapmaker 2.0 A250T 3in1 3Dプリンター

|

サイズ |

約405×424×490mm |

|

フレーム素材 |

アルミニウム合金 |

|

データ送信方法 |

Wi-Fi、USBケーブル、USBフラッシュドライブ |

|

タッチスクリーン |

5インチ、Android OS、クアッドコアA7 CPU @ 1.1GHz |

|

対応 |

ソフトウェア:SnapmakerLubanまたはサードパーティソフトウェア |

|

定格出力 |

320 W |

|

3Dプリント |

作業域:約230×250×235mm(W×D×H) |

|

レーザー彫刻 |

約230×250mm(W×D) |

|

CNC彫刻 |

約230×250×235mm(W×D×H) |

250エンクロージャー

|

重さ |

約14.2 kg |

|

サイズ |

約530×624×507mm |

|

素材 |

フレーム:アルミニウム合金 |

※ 注意

- レーザー光を直視するのは大変危険ですので、エンクロージャーで遮光するか、レーザーに対応したゴーグルを着用下さい。

- CNC加工中は対象物をしっかりと固定した上で加工を開始下さい。不安定な状態で無理な力が加わると対象物が治具から外れて周囲に飛散する恐れがあります。事故防止のため、当店ではエンクロージャーのご利用をお勧め致します。

- ご利用にあたっては付属の説明書をよく読み、危険行為を避け、本製品と互換性のある素材・ビットをお使い下さい。